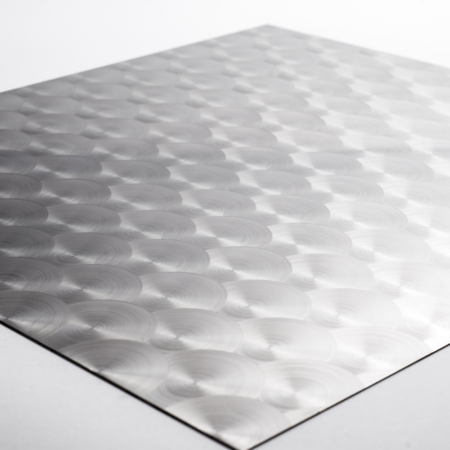

Stainless Steel Finishes

Please refer to the following table for stainless steel finishes details of their properties and characteristics.

Mill Finishes

Dull finish characteristic of steel after hot rolling, annealing and pickling. Generally used when smoothness and uniformity of finish are not important. It is permissible for grinding marks to be present. NOT SUITABLE FOR POLISHING WITHOUT SOME RISK.

A uniform, cold rolled, softened and descaled matt finish.

Cold rolled, softened, descaled and lightly rolled on polished rollers to produce a smooth but dull silky surface finish. FINISH MOST COMMONLY USED FOR POLISHING.

Cold rolled, reflective finish achieved through annealing. SUITABLE FOR POLISHING WHERE A BRIGHT FINISH IS REQUIRED.

Mechanically Polished Surfaces

A uniform coarse ground finish obtained by polishing with 80 to 100 grit abraisives.

A uniform coarse ground finish obtained by polishing with 180 to 220 grit abrasives. THIS FINISH IS GENERALLY DESCRIBED AS DULL BRUSHED.

A general satin polish produced by using successively finer abrasives between 180 and 240 grit. This achieves a fine grain non-reflective finish. There are trade named variations of this finish produced by some specialist polishers which are available.

A satin polish similar to 240 grit, but with cleaner cut surface finish and a lesser RA of surface roughness.

A bright buffed polish most suitably applied to 2B or B/A finishes: achieved by using a fibre and/or cloth mop with a suitable polishing compound.

A bright reflective finish with a high degree of image clarity. Produced by polishing with successively finer grits followed by buffing with very fine polishing compounds. THIS FINISH IS DESCRIBED AS BRIGHT OR MIRROR POLISHED.

Stainless Steel Grades

Please refer to the table below for details of the properties, features and application of various Austenitic and Ferritic grades of steel available.

Austenitic Steel Grades

| Grade | Cold Forming | Welding | Corrosion Resistance | Max Service Temp. (oC) | Special Features | Typical Applications |

|---|---|---|---|---|---|---|

| 304 S11 (1.4307) | V | E | V | 400 | Low carbon for improved welding | Boilermaking, nuclear & heat exchanges |

| 304 S15 (1.4301) | V | V | G | 400 | Standard sheet metalworking grade similar to 304 S31 | Catering, food, brewery, dairy & ducting industries |

| 304 S16 (1.4306) | E | V | G | 400 | Deep drawing quality | Sinks, holloware trade |

| 304 S31 (1.4301) | G | V | G | 400 | Standard sheet metalworking grade similar to 304 S15 | Catering, food, brewery, dairy & ducting industries |

| 321 S31 (1.4541) | G | E | V | 800 | T.I. stabilised for reduced weld decay at high tempreatures | Boilermaking, heat resistors, aeronautics & pipes |

| 316 S11 (1.4404) | V | E | E | 400 | Low carbon for improved welding and corrosion resistance | chemical works, marine, brewery & food industries, road tankers |

| 316 S31 (1.4401) | G | V | E | 400 | Corrosion resistance | chemical works, marine, brewery & food industries, road tankers |

| 310 S24 (1.4845) | F | V | V | 1100 | High service temperature resistance | Furnace work |

Ferritic Steel Grades

| Grade | Cold Forming | Welding | Corrosion Resistance | Max Service Temp. (oC) | Special Features | Typical Applications |

|---|---|---|---|---|---|---|

|

430 S17 (1.4016) |

G | G | F | 800 | Standard sheet metalworking grade for low quality applications | Decorative household items & ducting |

E=Excellent; V=Very Good; G=Good; F=Fair; P=Poor; N=Not Recommended