Non-Heat Treatable Alloys

E=Excellent; V=Very Good; G=Good; G*=Good but not guaranteed; F=Fair; P=Poor; N=Not Recommended

| Grade | Most commonly used tempers | Characteristics | Typical uses | Most common forms available | Cold forming | Machining | Anodising | Durability | Inert- gas shielded arc welding (MIG & TIG) | Resistance welding (spot. Seam, flash, butt or stud) |

|---|---|---|---|---|---|---|---|---|---|---|

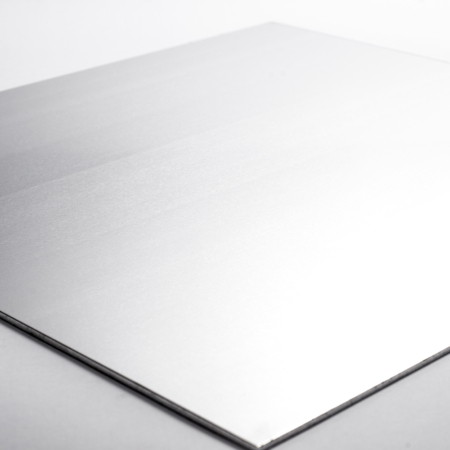

| 1050A | H14/H24 | 99.5% Pure aluminium. Malleable. Good corrosion resistance. Easily weld-able. | Non-structural tanks and vats in the food and chemical industry. Heat exchangers. | Sheet, Shate, Tube | V | F | G* | V | E | V |

| 1200 | H14/H24 | 99.0% Pure aluminium. Malleable. Good corrosion resistance. Easily weld-able. | Non-structural tanks and vats in the food and chemical industry. Heat exchangers. | Sheet, Shate, Tube | V | F | G* | V | E | V |

| 3103 | H14 | Low to medium strength aluminium-manganese alloy with good ductility, corrosion resistance and weld-ability. | Chemical equipment, storage tanks, vehicle bodies. | Sheet | V | F | G* | V | E | E |

| 5005 | H14 | Anodising quality | Architectural uses. Panelling. | Sheet | G | G | V | V | V | V |

| 5251 | 0/F/H22 | Medium strength aluminium-magnesium alloy with good ductility, weld-ability and high corrosion resistance. | Marine, road and rail transport, storage tanks, silos, drilling rigs, anodised parts. | Sheet, Shate, Plate, Tube. | G | G | G* | V | V | E |

| 5454 | F/H111(O) H114 | High strength aluminium-magnesium alloy. Ductile in the soft condition. Tough, weld-able, with high corrosion resistance. | Welded structures, tipper bodies, tankers and storage tanks. | Sheet, Shate. | V | V | G* | V | V | E |

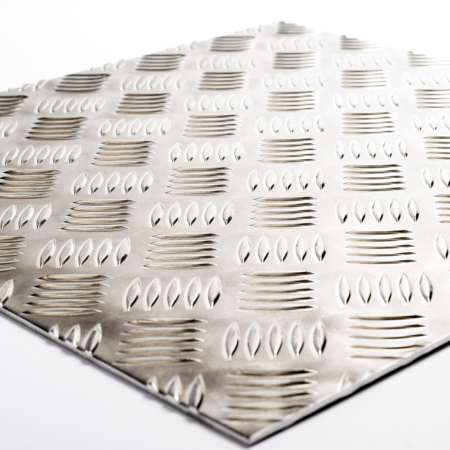

| 5754 | F/H111(O) | High strength aluminium-magnesium alloy. Ductile in the soft condition. Tough, weld- able, with high corrosion resistance. | Treadplate flooring, walkways, trolleys, kick plates, ramps, lifts, cold rooms. | Sheet, Shate, Treadplate. | V | V | G* | V | V | E |

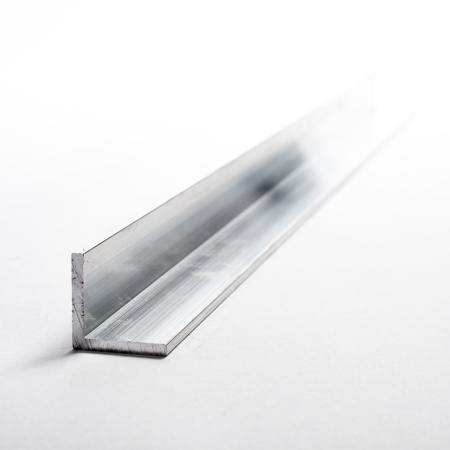

| 5083 | F/H111(O) | High strength aluminium –magnesium alloy. Ductile in the soft condition. Tough, weld-able, with high corrosion resistance. | Marine, road and rail transport. Cryogenic pressure vessels, storage tanks, silos, drilling rigs. | Sheet, Shate, Plate, Extrusions, Tube. | G | E | G* | V | E | E |

Heat Treatable Alloys

E=Excellent; V=Very Good; G=Good; G*=Good but not guaranteed; F=Fair; P=Poor; N=Not Recommended

| Grade | Most commonly used tempers | Characteristics | Typical uses | Most common forms available | Cold forming | Machining | Anodising | Durability | Inert- gas shielded arc welding (MIG & TIG) | Resistance welding (spot. Seam, flash, butt or stud) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1050A | H14/H24 | 99.5% Pure aluminium. Malleable. Good corrosion resistance. Easily weld-able. | Non-structural tanks and vats in the food and chemical industry. Heat exchangers. | Sheet, Shate, Tube | V | F | G* | V | E | V |

| 1200 | H14/H24 | 99.0% Pure aluminium. Malleable. Good corrosion resistance. Easily weld-able. | Non-structural tanks and vats in the food and chemical industry. Heat exchangers. | Sheet, Shate, Tube | V | F | G* | V | E | V |

| 3103 | H14 | Low to medium strength aluminium-manganese alloy with good ductility, corrosion resistance and weld-ability. | Chemical equipment, storage tanks, vehicle bodies. | Sheet | V | F | G* | V | E | E |

| 5005 | H14 | Anodising quality | Architectural uses. Panelling. | Sheet | G | G | V | V | V | V |

| 5251 | 0/F/H22 | Medium strength aluminium-magnesium alloy with good ductility, weld-ability and high corrosion resistance. | Marine, road and rail transport, storage tanks, silos, drilling rigs, anodised parts. | Sheet, Shate, Plate, Tube. | G | G | G* | V | V | E |

| 5454 | F/H111(O) H114 | High strength aluminium-magnesium alloy. Ductile in the soft condition. Tough, weld-able, with high corrosion resistance. | Welded structures, tipper bodies, tankers and storage tanks. | Sheet, Shate. | V | V | G* | V | V | E |

| 5754 | F/H111(O) | High strength aluminium-magnesium alloy. Ductile in the soft condition. Tough, weld- able, with high corrosion resistance. | Treadplate flooring, walkways, trolleys, kick plates, ramps, lifts, cold rooms. | Sheet, Shate, Treadplate. | V | V | G* | V | V | E |

| 5083 | F/H111(O) | High strength aluminium –magnesium alloy. Ductile in the soft condition. Tough, weld-able, with high corrosion resistance. | Marine, road and rail transport. Cryogenic pressure vessels, storage tanks, silos, drilling rigs. | Sheet, Shate, Plate, Extrusions, Tube. | G | E | G* | V | E | E |